In order to ensure that the mechanical equipment is always in good technical condition and can be put into operation at any time, reduce the failure downtime, improve the mechanical integrity and utilization rate, reduce mechanical wear, prolong the service life of the machinery, and reduce the mechanical operation and maintenance costs, energy-saving intelligent motors and fans are being more and more used in mechanical equipments and systems.

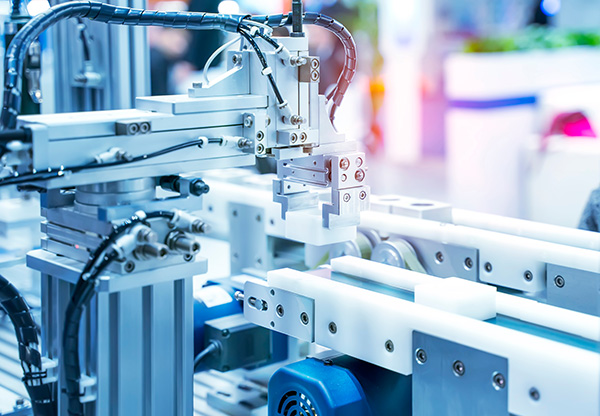

There are many kinds of mechanical equipment. When the mechanical equipment is running, some of its components and even itself can carry out different forms of mechanical movement. Mechanical equipment consists of driving device, speed change device, transmission device, working device, braking device, protective device, lubrication system, cooling system, etc.

The heat dissipating motor has always been linked to mechanical equipment in various industries. During operation, the machine generates a lot of heat between parts. In order to maximize the surface area of its contact with surrounding cooling media (such as air) and achieve the purpose of heat dissipation, a PBM fan can be used. The mechanical arm is equipped with a heat dissipating tooth shape design at the joint of the shell, and an axial flow fan is installed on the outer side of the mechanical arm shell, and a cover plate is added for the air duct design, Transfer the heat generated by the mechanical equipment to the external air, allowing the temperature of the equipment to be adjusted.