All Rights Reserved Privacy Policy Site Map

FOCUS ON EC FAN ONLY

FOCUS ON EC FAN ONLY

When you’re in the market for centrifugal fans for an industrial facility, you’ll have plenty of options to choose from. One of the types of centrifugal fans that you may consider buying is backward-curved centrifugal fans. Today we will give you a brief introduction of backward-curved centrifugal fans.

The centrifugal fan is a machine that relies on the input mechanical energy to increase the air pressure and discharge the air distribution. It is a driven fluid machine. Centrifugal fans are widely used in ventilation, dust removal and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings; ventilation and induction of boilers and industrial furnaces; cooling of air conditioning equipment and household appliances ventilation; drying and selection of grain; wind tunnel wind source and inflation and propulsion of hovercraft, etc.

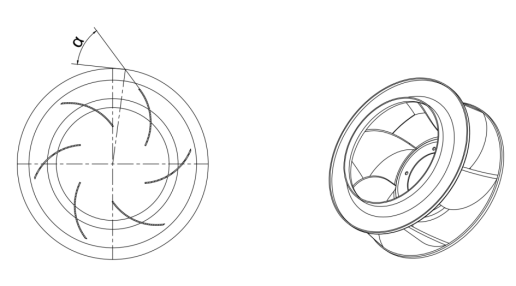

The impeller outlet angle α of the centrifugal fan is less than 90 degrees, as shown in the figure below and the fan is rotating clockwise, and the performance of the backward impeller is mainly medium pressure.

When the wind wheel rotates, a pressure difference is generated on the wind wheel. On the convex surface of the impeller, when the wind wheel rotates, a suction force is generated in the air to generate positive pressure. The impeller blades push the air outward, spreading it around in a radial fashion. On the concave side of the impeller blades, as the fan turns, negative pressure is created that draws air into the gaps between the blades. During continuous rotation, this air is dispersed by the blades below. The impeller sucks air from the center of the fan, changing the direction of the airflow between the impeller inlet and the 90° exhaust port.

Centrifugal fans are composed of impellers, motors and wind guide rings.

1. The impeller is composed of plastic/aluminum impeller, etc., and has been statically and dynamically balanced to ensure stable rotation and good performance;

2. The temperature rise of the motor is low, and the ventilation and heat dissipation are self-cooling;

3. Wind guide ring is to ensure that the airflow enters the wind rotor blades evenly, so as to reduce the airflow noise generated by the airflow.

The design and manufacture of backward centrifugal fans have the highest theoretical efficiency and can adapt to harsh environments. In order to ensure the highest reliability, the motors used in tropical areas are IP55 standard and use F absolute grade. Light weight, high strength, and good toughness;

The back-curved impeller has a compact structure and is designed through aerodynamics, which can adapt to high static pressure systems;

The backward curved centrifugal fan uses negative pressure to draw air, and with super suction, the indoor and outdoor air are exchanged, and the indoor hot air, peculiar smell, and dirty air are discharged. The backward low power consumption makes it more energy-saving, and the structure is compact and occupies less space. Large air volume makes the equipment more efficient and powerful in purification;

Because the impeller is backward inclined, it is not easy to adhere to dust and other media, and there is no need to disassemble the machine for maintenance and cleaning, saving time and effort.

It is mainly used for air purification, AHU/FFU, purification unit, ventilation duct dust removal, purification of air conditioning systems, environmental protection and pollution control and other refrigeration equipment.

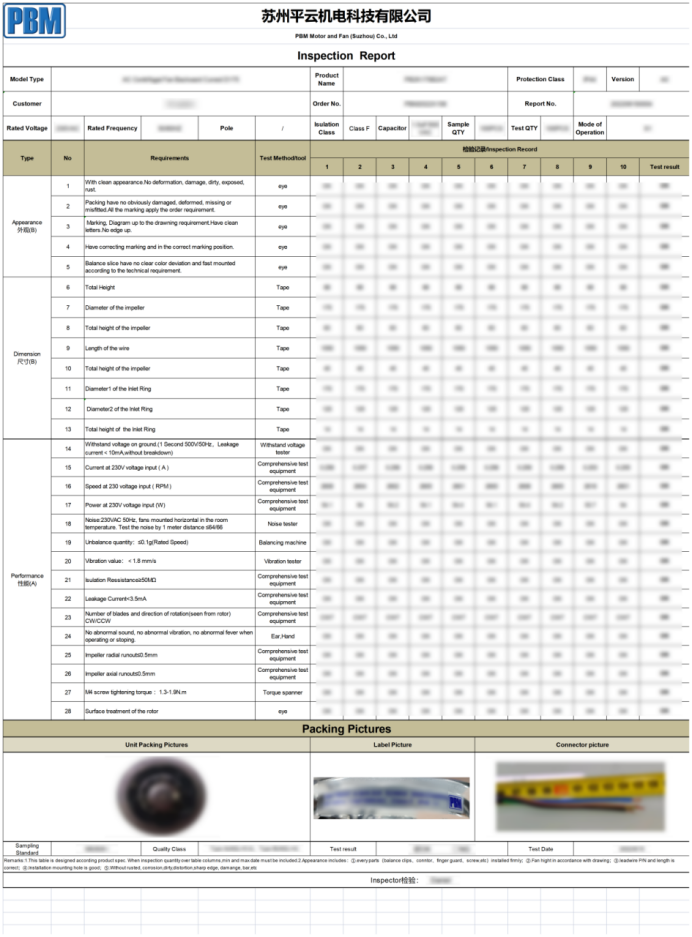

1. Appearance; 2. Size; 3. Performance; 3. Fill out the shipping report; 4. Packaging。

We will not deliver the goods until we have completed the following process and passed it.

PBM is a China mainland EC(Electronically Commutated) brushless motor manufacturing and technology consulting company offering an extensive range of EC motors, fans and intelligent ventilation solutions for air-moving precisely and constantly with maintenance-free throughout the life cycle of products in the last decades. For more information about backward curved centrifugal fans, please do not hesitate to contact us.

By continuing to use the site you agree to our privacy policy Terms and Conditions.