All Rights Reserved Privacy Policy Site Map

FOCUS ON EC FAN ONLY

FOCUS ON EC FAN ONLY

In the world of ventilation and air circulation, two main players stand out: axial fans and centrifugal fans. These devices play a crucial role in maintaining comfortable indoor environments and supporting industrial processes. However, their designs, applications, and performance characteristics set them apart. In this article, we'll explore the key differences between axial and centrifugal fans to help you make an informed choice for your specific ventilation needs.

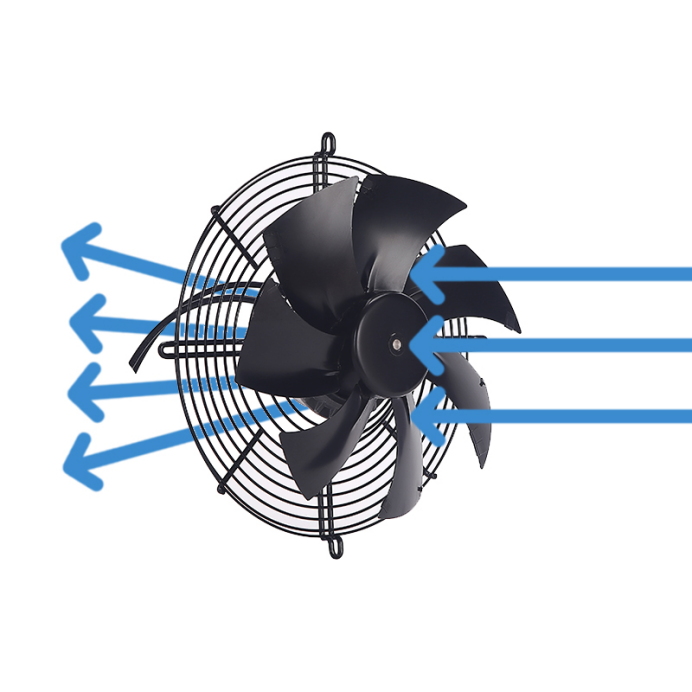

Axial fans are primarily composed of components such as impellers, casings, and motors. Renowned for their uncomplicated design and efficient airflow patterns, axial fans are celebrated for their ability to intake air in a direction parallel to the fan's axis and expel it in the same manner. Positioned securely in place, these fans facilitate the movement of air.

Axial fans are primarily comprised of impellers and casings, boasting a simple structure that demands meticulous data precision. In essence, axial fans find application in diverse settings such as factories, warehouses, offices, residences, and more, serving as efficient ventilation solutions. They also excel in larger industrial spaces or data centers, working seamlessly with cooling apparatus like air coolers, evaporators, condensers, spray systems, and more. Additionally, axial fans designed for mining, anti-corrosion, and explosion-proof purposes are crafted using corrosion-resistant materials and explosion-proof measures, paired with corresponding explosion-proof motors. This makes them suitable for conveying gases that are explosive, volatile, or corrosive. This design is exceptionally well-suited for scenarios requiring consistent airflow and cooling.

The installation of axial fans is relatively straightforward, making them a favored choice for a wide array of ventilation applications.

While axial fans excel in providing a high volume of air, they often lack significant pressure capabilities. This limits their effectiveness in scenarios where air needs to be moved through long ducts or overcome substantial resistance. Additionally, axial fans may struggle with applications that demand higher pressure differences.

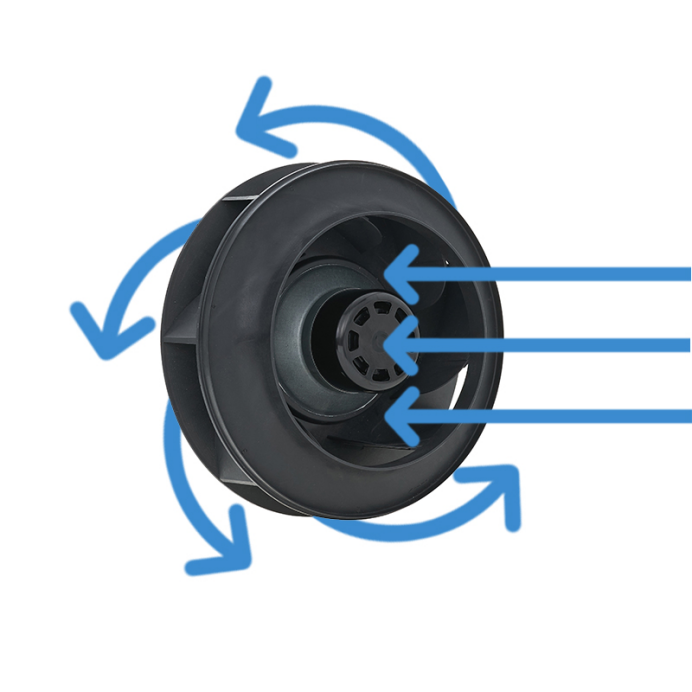

Centrifugal fans are designed for versatility, offering higher pressure capabilities compared to axial fans. Their operational principle involves utilizing a rotating impeller to generate centrifugal force, propelling air perpendicular to the fan axis. Functioning as mechanical devices that convert input mechanical energy into increased gas pressure and subsequent gas movement, centrifugal fans fall under the category of dynamic fluid machinery.

This distinctive design empowers centrifugal fans to overcome resistance, rendering them indispensable for scenarios involving lengthy pipelines, confined spaces, or intricate ventilation routes. Widely deployed across factories, mines, tunnels, cooling towers, vehicles, ships, and buildings, centrifugal fans serve diverse purposes including ventilation, dust extraction, and cooling. They find application in ventilating and inducing airflow for boilers and industrial furnaces, as well as for cooling and ventilation in air conditioning systems and household appliances. Centrifugal fans are also crucial for grain drying and conveying, wind tunnel air supply, and inflatable propulsion for hovercrafts.

Centrifugal fan impellers are thoughtfully designed with a backward-curved configuration, enabling frictionless operation, remarkably low noise emissions, and resistance to dust accumulation. Maintenance is conveniently facilitated by this design. The impellers of centrifugal fans are often crafted from fiberglass-reinforced plastic, boasting robust resistance to oxidation and corrosion.

In essence, the adaptability and exceptional attributes of centrifugal fans underscore their essential role across a broad spectrum of applications.

Centrifugal fans, while effective in pressure generation, might have lower overall airflow compared to axial fans. Their installation can be more complex due to the need to accommodate the perpendicular air movement. This can result in a larger footprint and additional considerations during setup.

When deciding between axial and centrifugal fans, several factors come into play:

When your primary objective involves moving a significant volume of air with minimal resistance, an axial fan might be the superior choice. Axial fans offer relatively larger air volumes and lower air pressure, essentially generating minimal pressure. On the other hand, centrifugal fans deliver substantial air volumes and higher air pressure. In scenarios where there are multiple pipe bends, longer exhaust and supply distances, and significant pipe resistance, applications necessitating higher pressure to overcome resistance call for the use of centrifugal fans.

Axial fans' compact design makes them well-suited for environments with limited space. On the other hand, centrifugal fans can adapt to various installation scenarios, making them a better fit for confined or complex spaces.

Due to their straightforward design, axial fans are generally easier to install. They are typically mounted directly onto walls or connected to ducts. Centrifugal fans may require more planning and adjustments, particularly when dealing with intricate piping systems or specific installation constraints.

Axial fans usually have a cylindrical shape, while centrifugal fans exhibit a scroll or spiral shape.

The motor connection for axial fans is commonly located within the fan's housing, whereas centrifugal fans have their motor connected via a shaft, often situated outside the fan's exhaust duct.

In the world of ventilation solutions, the choice between axial and centrifugal fans is crucial, and it's a decision that PBM, a leading EC (Electronically Commutated) brushless motor manufacturer and technology consultant based in China mainland, is well-equipped to assist you with. PBM specializes in providing a diverse array of EC motors, fans, and intelligent ventilation solutions that ensure precise and consistent air movement. With a commitment to excellence, PBM's products are designed for maintenance-free performance throughout the lifecycle, a testament to the company's dedication to quality and innovation over the past decades. When you partner with PBM, you're not only choosing the optimal fan technology for your needs but also benefiting from a legacy of expertise and reliability. Make the smart choice today and experience the difference that PBM's cutting-edge solutions can bring to your ventilation projects.

By continuing to use the site you agree to our privacy policy Terms and Conditions.