All Rights Reserved Privacy Policy Site Map

FOCUS ON EC FAN ONLY

FOCUS ON EC FAN ONLY

Centrifugal fans are an indispensable tool in many industries, ranging from HVAC systems to industrial air movement. However, with so many options available, choosing the right one can be a daunting task. In this post, we will explore the different types of centrifugal fans and the selection criteria you should consider when buying one.

The most important principle of choosing a fan is to use the air flow reasonably to achieve the required function

The materials used in constructing the fan can impact its performance, durability, weight, and cost. For instance, fans made from steel tend to be heavier but are more durable and better suited for rugged or corrosive environments. On the other hand, aluminum fans are lighter and less expensive, making them a good choice for less demanding applications,At the same time,PA66+GF Material of Impeller can reduce fan weight, save transportation costs, and achieve energy saving effect,PA66 has the characteristics of temperature resistance, flame retardant, corrosion resistance, heat insulation, high tensile strength and good electrical insulation,This allows PBM Fan to reach-25℃~+60℃。

The operating environment of the fan is another important consideration. The temperature and humidity levels of the space where the fan will operate can affect its performance and lifespan. Some fans are designed to withstand extreme temperatures, while others may require additional cooling measures.

Maintenance requirements should also be factored into the decision-making process. Fans with simple designs and fewer moving parts typically require less maintenance than those with more complex structures. It's important to evaluate the cost and frequency of maintenance to determine the total cost of ownership over the life of the fan.

Depending on the application and location, there may be regulatory requirements that must be met when selecting a centrifugal fan. For example, some industries have specific safety regulations related to fan operation and maintenance. It's important to research any applicable regulations and ensure the fan meets the necessary requirements.

Finally, cost considerations are an important factor when purchasing a centrifugal fan. The cost of a fan can vary widely depending on its size, construction materials, and features. However, it's important to remember that the initial cost is just one component of the overall cost of ownership.

A fan with higher efficiency may have a higher upfront cost but can result in lower energy costs over time. Additionally, fans with lower maintenance requirements may have a higher upfront cost but can save money on repairs and downtime in the long run.

When considering cost, it's essential to evaluate the fan's lifetime cost and weigh it against the potential benefits in terms of performance and efficiency.

Air flow: volume of air conveyed by the fan per minute (m³/h)

Total pressure: energy possessed by gas, equal to dynamic pressure + static pressure (Pa)

Dynamic pressure: pressure required to accelerate gas from zero velocity to a certain velocity (Pa)

Static pressure: difference between absolute pressure at a point and atmospheric pressure for fluids (Pa)

Fan speed: number of rotations per minute made by the fan impeller (RPM)

Shaft power: actual power transmitted from the motor to the fan shaft, excluding external loss factors. Typically considered as the actual power required by the fan (KW)

Noise: noise generated by aerodynamic and mechanical noise during normal operation of the fan; most manufacturers report dB(A) at 1.0m distance

Overall Pressure Efficiency: Airflow x Total Pressure / Shaft Power / 1000 / 3600 x 100%

Power supply: AC: 380~3, 220~3, 220~1, 110~1, DC: 310, 110, 85, 48, 24, 12, etc.

Outlet wind speed: wind speed at the cross-sectional area of the fan outlet. Controlling the outlet wind speed can indirectly control the noise level (m/s).

Purchasing the right centrifugal fan involves taking multiple factors into account. At PBM, we are a China mainland EC brushless motor manufacturing and technology consulting company that offers an extensive range of EC motors, fans, and intelligent ventilation solutions. Our Campany have 15 years experience and Five Years Warranty for all of our EC fan products;Our products are designed to provide precise and constant air-moving with maintenance-free operation throughout their life cycles. If you are looking for a reliable and energy-efficient centrifugal fan, don't hesitate to contact us today. Our team of experts can help you choose the best solution to meet your specific needs and ensure optimal performance, efficiency, and cost-effectiveness.

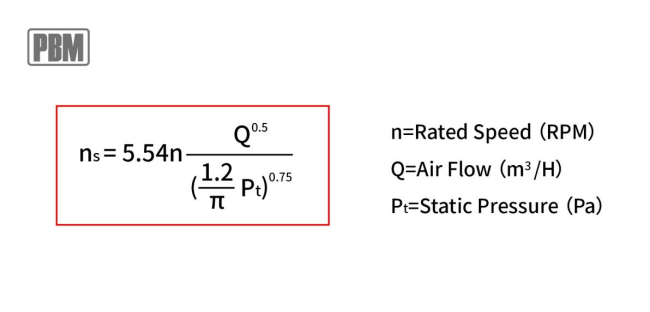

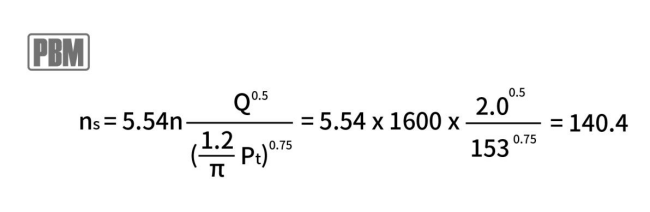

For example, in 2022, a French customer has a requirement for PBM to provide an underground ventilation system for a winery. When the fan rotates at n=1600rpm, the airflow required is 2.0m³/s with a total pressure of 400Pa, assuming standard intake conditions. The appropriate type of fan should be selected to meet these requirements.

We apply the formula to get the final 140.4.

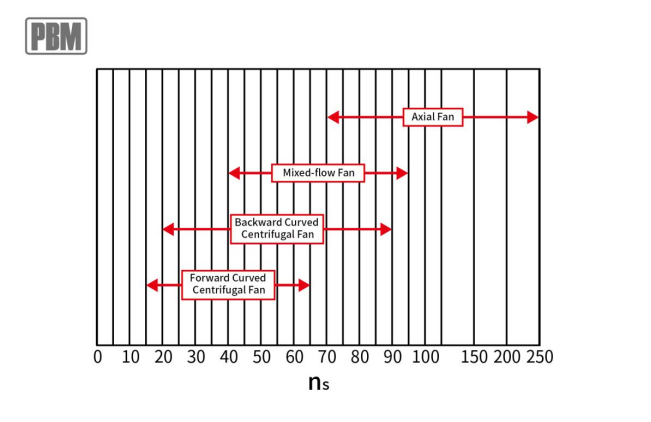

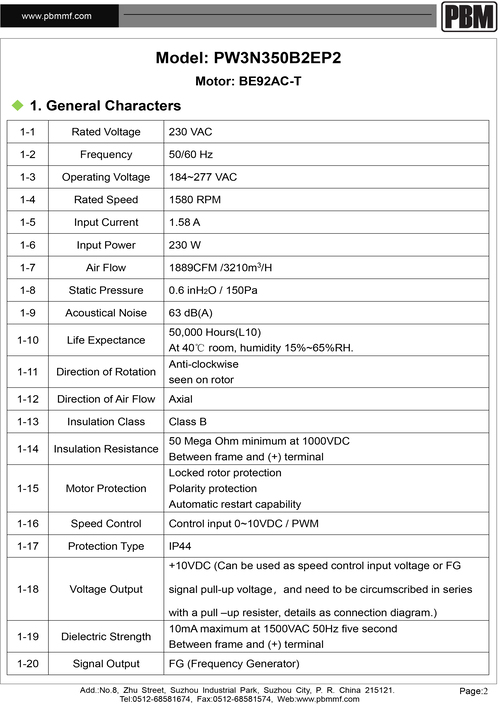

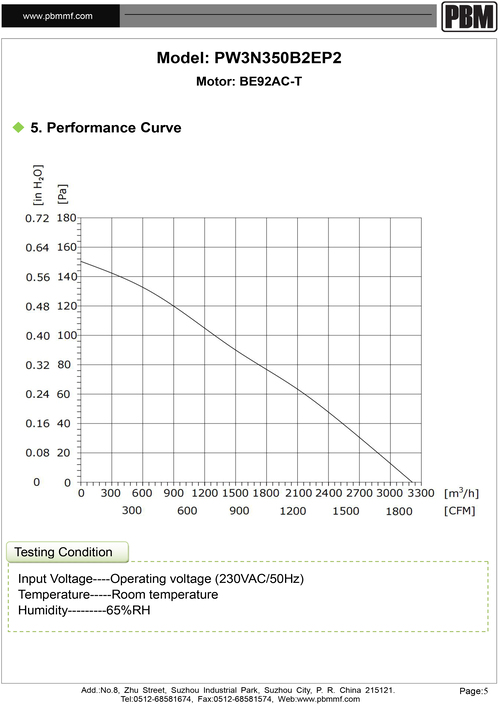

Combined with the figure below, it can be concluded that 140.4 is suitable for Axial Fan, and then we chose this axial fan PW3N350B2EP2 from PBM.

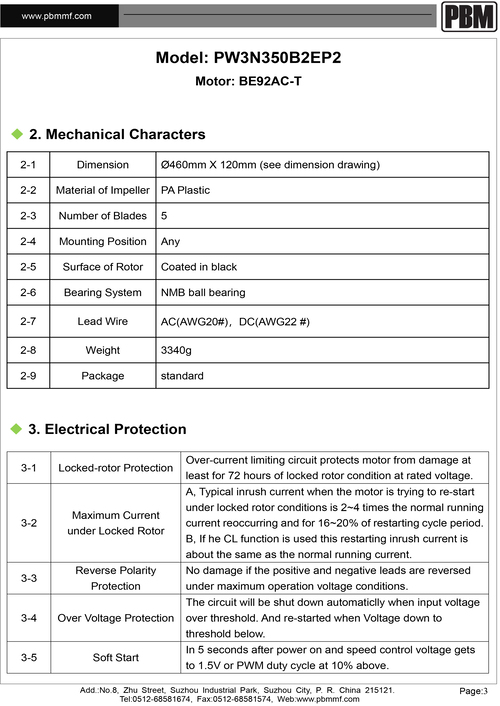

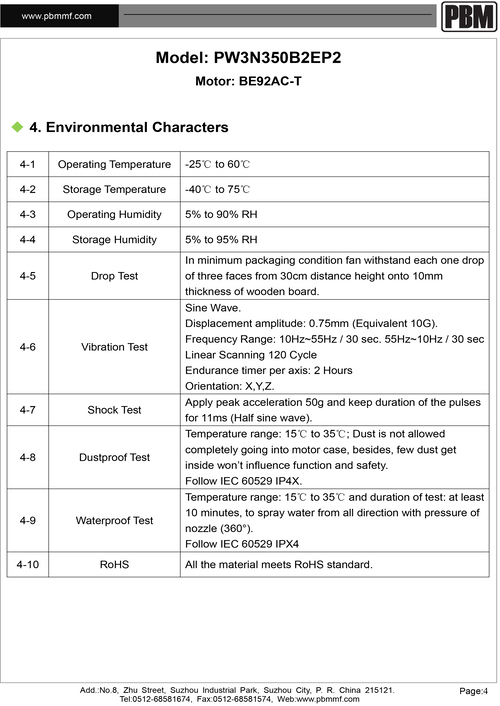

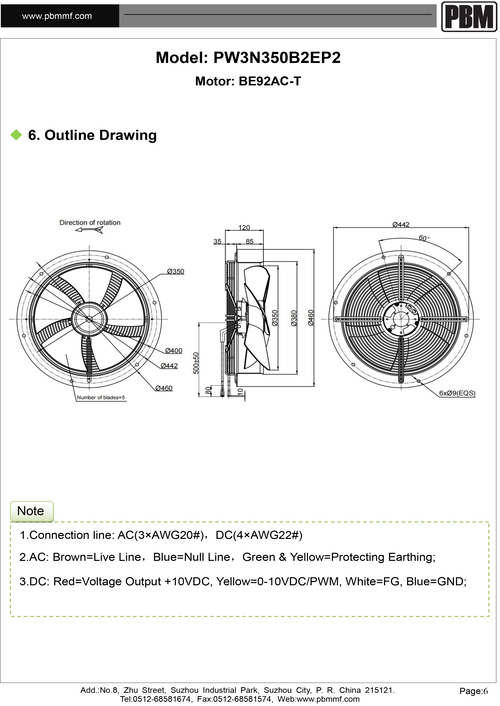

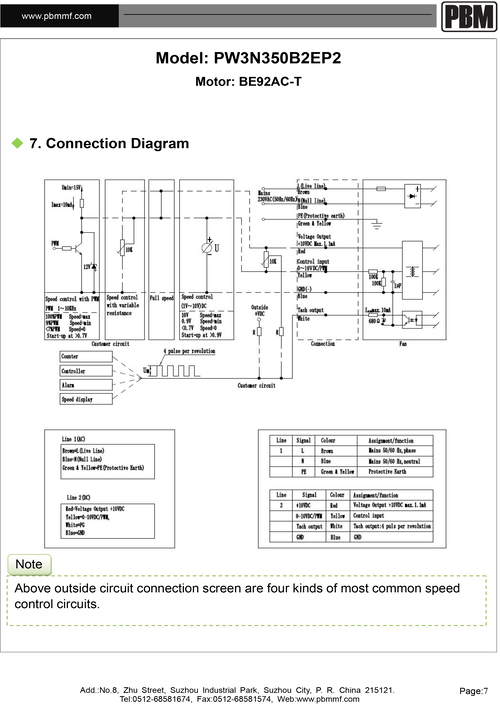

These are the specification sheets for our PW3N350B2EP2.

After three days of production,we completed two prototypes and delivery to place.

Welcome to contact us for centrifugal fans. www.pbmmf.com

By continuing to use the site you agree to our privacy policy Terms and Conditions.